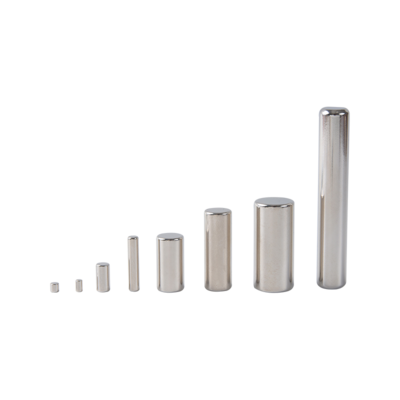

Cylinder neodymium magnets are a type of permanent magnet made from an alloy of neodymium, iron, and boron. As the name suggests, they are cylindrical in shape and are often used in applications where a long, narrow magnet is required. Cylinder neodymium magnets are commonly used in a range of industries, including automotive, aerospace, medical, and consumer electronics. They are known for their high magnetic strength and excellent resistance to demagnetization. Cylinder neodymium magnets come in a range of sizes and strengths and are often used in pairs or groups to achieve a desired magnetic force. They should be handled with care due to their strong magnetic field, and proper safety precautions should be taken to avoid injury or damage.

Cylinder neodymium magnets have several characteristic features, including:

High magnetic strength: Cylinder neodymium magnets are known for their high magnetic strength, making them ideal for a wide range of applications where a strong magnetic field is required.

Resistance to demagnetization: Neodymium magnets have excellent resistance to demagnetization, meaning they are able to maintain their magnetic strength over long periods of time.

Small size: Cylinder neodymium magnets can be made in small sizes relative to their magnetic strength, making them ideal for applications where space is limited.

Corrosion resistance: Neodymium magnets can be prone to corrosion, but they can be coated with materials such as nickel or epoxy to protect them from damage.

Brittle: Neodymium magnets are quite brittle and can crack or shatter if dropped or exposed to sudden impacts. Care should be taken when handling these magnets.

Temperature sensitivity: Neodymium magnets can lose some of their magnetic strength at high temperatures, so they may not be suitable for use in applications where high temperatures are present.