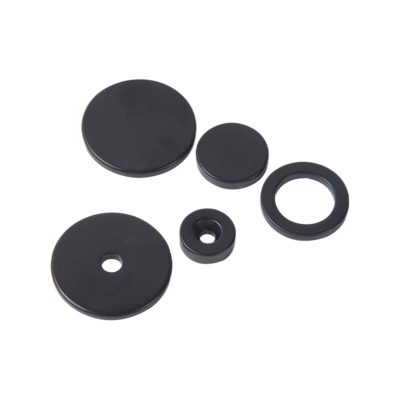

A

black epoxy coating neodymium magnet is a type of permanent magnet that is made from neodymium, a rare earth metal, and coated with a layer of black epoxy. The black epoxy coating provides several benefits, including increased corrosion resistance, improved insulation, and enhanced cosmetic appearance.

One of the main benefits of a black epoxy coating on a neodymium magnet is increased corrosion resistance. The epoxy layer acts as a barrier to prevent oxidation and corrosion of the underlying neodymium material, which can be particularly important in applications where the magnet will be exposed to harsh environments or corrosive substances.

In addition, the black epoxy coating can also improve the insulation of the magnet. This can be useful in electrical applications where the magnet is used in electrical circuits, as the improved insulation can help to prevent short circuits and ensure safe operation.

Finally, the black epoxy coating can also enhance the cosmetic appearance of the magnet, making it an attractive choice for applications where appearance is important. For example, black epoxy-coated neodymium magnets are often used in electronics and machinery where a sleek and professional appearance is desired.

Overall, a black epoxy-coating neodymium magnet provides a number of benefits, including increased corrosion resistance, improved insulation, and enhanced cosmetic appearance. These benefits make it a popular choice for a wide range of applications.

Magnetic strength: The magnetic strength of a black epoxy-coating neodymium magnet is one of the most important factors to consider. You should choose a magnet with the right strength for your application, taking into account factors such as the size and weight of the objects you need to attract, and the environment in which the magnet will be used.

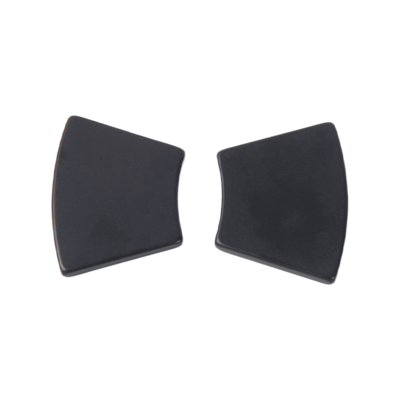

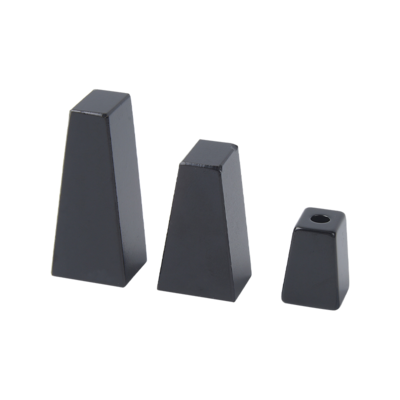

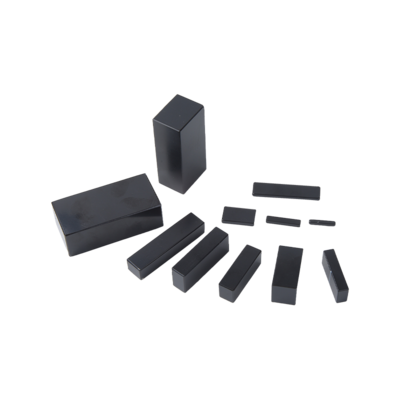

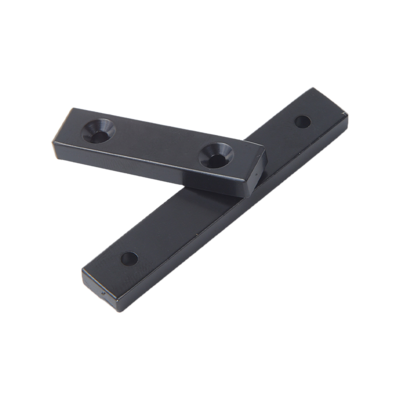

Size and shape: The size and shape of the magnet can be important for a variety of applications, such as fitting into tight spaces or conforming to a specific surface. You should choose the size and shape of the magnet based on your specific requirements.

Material and coating: The material and coating of the magnet are also important factors to consider. The black epoxy coating provides increased corrosion resistance and improved insulation, but you should also consider factors such as the compatibility of the coating with other materials and the environment in which the magnet will be used.